Solar designers are often put in no-win situations.

Despite being given imperfect data from satellite imagery or manual measurements, designers are expected to deliver perfectly accurate designs. On top of that, many designers are put under immense pressure to deliver specific quotas each day regardless of the complexity of the roof.

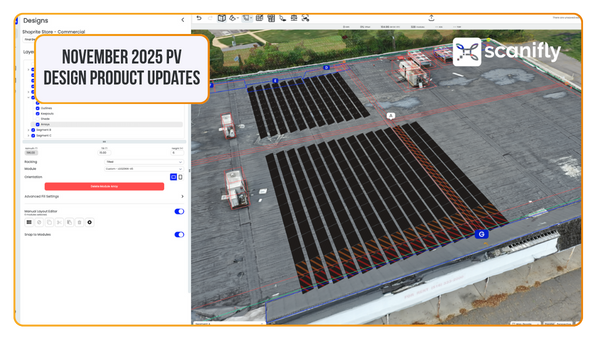

At Scanifly, we spoke to designers around the world and asked them how companies can make it easier to deliver high quality designs without burning out. Here are four things they said would have a huge impact.

1. Set better sales and preliminary design expectations

A lot of issues arise from overly optimistic preliminary designs. We understand that contractors need to run a business, but when designers are handed max-filled prelim designs based on grainy satellite images, there is a higher risk of change orders and problems.

Instead, sales teams should be as conservative as possible without compromising the sale. For example, if the satellite image shows a distortion that might be a vent pipe, act like it is and say you can’t put a panel there in the preliminary design, but might be able to add a panel later.

In conversations with potential customers, stress two things:

-

Preliminary designs are just that: preliminary.

-

You need to get someone on site to verify all the data, which is a normal part of the solar surveying process.

Customers would rather see panels added versus taken away, so setting more conservative initial expectations sets you up to delight customers while making life easier for designers.

2. Get context for the whole site

Designers can only work with the data they are given. That means if a team does manual surveys and only measures the roof area from the preliminary design, that’s all a designer is able to work with. Surveyors also may not map every obstruction on the roof, leaving more to guesswork.

Surveyors should instead use a drone to get the entire site context, showing all roof planes, obstructions, and measurements. Drone flying is equally or more accurate than hand measurements and is significantly safer for surveyors, eliminating the risk that someone could fall or drop a piece of equipment.

Here’s what you need for full-site context:

-

Roof: X, Y, and Z axes measurements and images for every roof plane, including obstructions on the roof.

-

Exterior: General site context including poles, trees, and neighbors that might cause shading issues.

-

Interior: Photos of attics and dead fronts plus measurements for conduit runs.

-

Opportunities for more panels: Easily include nearby buildings, like a garage, shed or carport so designers can see where they might place additional panels.

With full-site context, designers can more accurately plan the solar project because they have every piece of data they could possibly need. They might even find opportunities to add more panels, resulting in happier customers.

3. Update your spec sheets

Designers are in the middle of the broader solar process. They rely heavily on data provided by sales and surveyors via a spec sheet for each project, which is then used to create procurement and installation plans.

To make this whole process easier, it’s critical to provide the most updated spec sheets possible, including customer-specific information like:

-

What color panel the customer wants (Blue on silver? Black on black? etc.)

-

Are there specific aesthetic preferences for panel placement?

-

Where the customer would ideally like the inverter to go (Garage? Basement? etc.)

-

If the customer has specific additional electricity needs such as EV charging or backup storage.

When a designer has this information, they can plan out the design both from a layout perspective and from a procurement perspective, smoothing out the entire process, saving time and increasing customer satisfaction.

4. Bring flexibility into quotas

Quotas, meaning a specific number of projects a designer is expected to complete on a daily basis, are fairly standard in the solar design world, and most designers don’t have a problem with them. Many even say that quotas are motivational and help them focus their efforts.

Where designers run up against problems is incredibly strict quotas that have no wiggle room for real-life issues.

For example, a flat adobe roof in New Mexico might take 30 minutes to design. An old construction house in Massachusetts or a Texas house with 10 roof planes, on the other hand, could take 2-4 hours to design properly.

Designers don’t want to get rid of quotas, but say that adding some flexibility will go a long way.

-

Make the quota a range instead of a fixed number.

-

Instead of daily quotas, make a daily average quota that’s measured weekly.

With some flexibility in quotas, designers can avoid staring down a specific number and instead focus on what really matters: a high quality design that makes the installation process smooth and easy.

Business results and personal fulfillment can go together

Design is a pivotal piece of every solar project. After a survey, nearly everything hinges on a designer’s ability to produce a high quality, accurate procurement and installation plan. In the end, that means a better homeowner experience as well, while the entire business develops a reputation for dependability.

At the same time, designers know they are part of a team. Their role is important, but so is everyone else’s. With that in mind, designers aren’t looking for special treatment or implying they should get the easy way out. Instead, it’s about making changes to how the design process operates so that the entire solar project goes more smoothly.