Lighthouse Solar surveys every site before signing a contract so they can help customers understand exactly which system will work best for them.

The company’s consultative sales process also means that a single engineer will survey a site, design the project, and create plans necessary for permitting and installation. This process has served the company well, but it is also time consuming. To get more time back in their day and improve their project margins, the Lighthouse Solar team uses Scanifly.

Speaking with Scanifly, Jay Bramble at Lighthouse Solar explained how the company uses drones as a revenue driver and margin-increaser for its projects.

A consultative sales process

Every Lighthouse Solar sales conversation is about making sure the customer is getting the highest possible return on investment. To accomplish this, Lighthouse works across multiple different energy technologies including solar, battery-based systems, and hybrid systems. It also means that the company does a lot before getting a signed project order.

“We do a lot pre-contract and that used to include climbing up on the roof to take measurements,” said Jay. “We honed down our process and got good at training people, but it still took a lot of time.”

Instead of cutting corners on their sales process, Jay sought out ways to make the whole thing more efficient. Since surveys took up a lot of time and informed the rest of the sales process, that’s where he looked first.

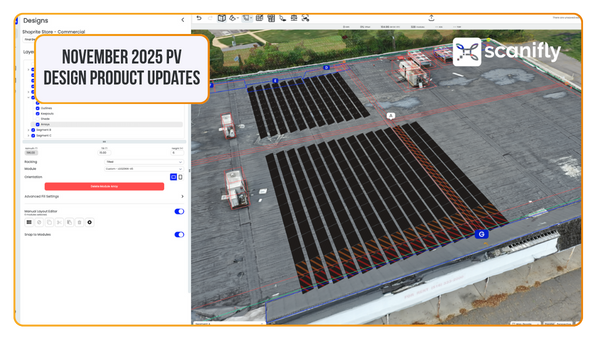

After assessing at multiple different solutions including LIDAR or even Google Earth, Jay and the Lighthouse team started using Scanifly to help them capture real-time data and site context.

How Scanifly helped drive revenue growth

The right kind of max fill: Jay said it’s common to run out of time on a survey and not measure the whole roof. It’s also common to not reach certain areas of the roof due to safety concerns. As a result, designers could only work with small portions of the roof. With Scanifly, designers can work with the whole roof, leading to higher ROI for customers and a bigger order for Lighthouse.

Never needing a margin for error: Jay said manual measurements always required a margin for error that’s now eliminated with Scanifly’s accuracy. This means no dead space when designing projects.

Customer requests for more panels: Jay said it’s fairly common for customers to ask if they can add more panels to preliminary designs. When doing this by hand, it often requires another truck roll. With Scanifly, the measurements are already there so they can easily add more modules to the roof.

Don’t waste your shade: Jay said that Scanifly’s accuracy, particularly around shading analysis, means they can put in more panels with confidence knowing they won’t be shaded over, which often results in more panels on the roof.

“Scanifly helps us see the whole array and plan the best layouts for customer ROI,” said Jay.

How Scanifly increased project margins

The first benefit Jay saw from using Scanifly was safety. Keeping people off roofs has been a financial win because the company needs less equipment (anchors, harnesses, ladders, etc.). But more importantly it’s a team win—Jay said roof accidents are all but inevitable and he feels much better knowing his team is safe and healthy on the ground. What’s better is that surveys are also significantly faster, taking about 15 minutes with a drone where they used to take 1-1.5 hours manually.

Beyond keeping employees off the roof, Jay said Scanifly made designing more efficient (cutting the time it takes to design a 3D model in half). Further, Lighthouse was able to cut some of their SketchUp licenses and use Scanifly’s design module instead, leading to direct cost savings.

From a project optimization perspective, Scanifly models make it easy to apply for relevant government rebates, easily accommodate design changes without additional truck rolls, and build comprehensive procurement plans.

The future of energy is ownership

Jay compares the future of solar to the American dream of homeownership. When people start doing well, they want to buy a house. He sees the same thing happening in solar—people will want to own their systems with solar and batteries rather than paying the grid or renting a system.

“We’re using more power than we ever have when you factor in things like electric cars and appliances,” said Jay. “But people still rent energy. I think in the future, we’re all going to own our energy production. It may not happen immediately, but I think our kids will see that in their lifetime.”