Rudy Garcia has watched the solar industry grow from the inside out during his 14 year career. He’s seen novel technologies, new ways of doing things, and the continued evolutions solar contractors must go through just to stay in business. Speaking with Scanifly, he shared his own career journey in the solar industry and how he’s navigating what he calls the “solar roller coaster” as the industry continues to expand.

How did you get into solar?

I have a background in digital media and started out working as a graphic designer. In 2007, I was introduced to the solar industry when I was hired to draw installation plans. The only problem was I knew nothing about electrical work or solar at the time, so I had to learn it all on the job. Luckily, my colleague taught me what I needed to know about the practical side of electricity and I read through the electrical code book for the legal and regulatory side.

From there, I learned jurisdiction-specific rules so I could educate county safety inspectors about our work process. Keep in mind, this was very early days and most people weren’t familiar with how solar panels worked. I actually was asked questions like “You’re telling me this piece of glass makes electricity?”.

While I started as a solar designer, I was promoted over a few years to managing multi-million dollars of residential solar projects. I was the third office hire at my first company Acro Electric; by the time I left there were over 150people. Eventually, that company was acquired by IES, and I moved onto a couple other companies including NRG Energy before starting my current role as a Design Engineer at CalSolar working on a multi-million dollar commercial project.

What are the biggest changes you’ve seen over the past 15 years?

Everything has changed on what I call the solar roller coaster. The rules that seemed written in stone beforehand no longer apply. The biggest shifts I’ve seen are:

Regulations: A lot of regulations – jurisdiction to jurisdiction – have changed as solar panels become more efficient and more common.

Technology: The old way of doing solar had zero technology outside of the panels themselves. Even bringing in AutoCAD for design was a huge upgrade back in the day. Now we’re seeing more technology throughout the entire process – from sales, to surveying, to design, to planning and even installation.

Pace of change: The industry was never static, but changes came a lot more slowly in the past. Now, you have to keep your pedal to the metal the whole time. You can’t ever really take your time.

Competition: Modern solar is a very fast and very aggressive industry. It used to be run by hippies back in the 1960s and 1970s. Now you’re seeing new firms popping up all over the nation.

What’s the role of technology in the solar industry today?

In terms of the “role” of technology, I’d say it’s two things: time savings and cost savings.

When I first got into the industry, technology was rudimentary. At best, you could draw vector lines, but people still relied on hand sketches. I personally used Illustrator and Visio Works for my early years. This was a time consuming process (especially the manual surveying), which meant paying for more labor and forwarding that cost to the customer.

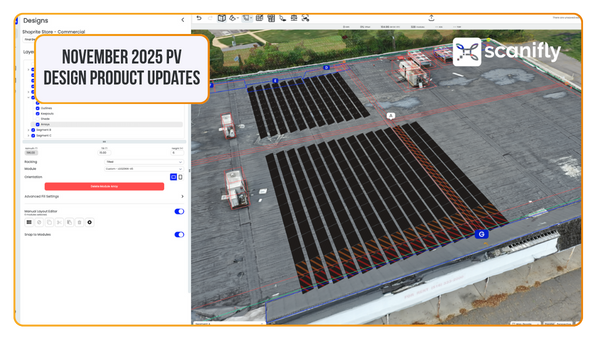

Things are different now. We have advanced AutoCAD modules, so our designs are much more thorough than they were before. But we’re also using drones and Scanifly software for our survey process: drones are great for capturing the images, then Scanifly’s solar design software makes it easy to render the images, download AutoCAD files, and design from there. The whole thing is way more efficient and cost effective, creating better customer (and employee) experiences.

Where do drones fit into your work?

Working with drones is day and night compared to how things were when I started in the industry. But it wasn’t easy. It actually took me two years to convince my first boss to give drones a try back in 2018.

I invited him to a fairly standard sized commercial site – a 500 kW project – to show him how drones would help. First, I had to measure the building (it was U shaped). Second, I had to manually measure 200 white PVC vents that satellite imagery missed. Third, I needed to walk about seven miles around the building, manually scoping the HVAC units with a SunEye to do shading analysis.

With a drone, the whole project took about 30 minutes with just me. Doing it manually, I would have needed a full day or two (with another surveyor on site for safety purposes). In our business, a truck roll costs about $270. So we’re saving a ton of money with one 30 minute trip versus 3-4 truck rolls to do the same project manually – and 3-4 truck rolls assumes you did it correctly the first time. If you mess up even a little bit on shading analysis or measurements, you have to go back out.