Your job as a Solar Surveyor is not to become an electrical expert; it’s to collect the right data so Designers can do their job. In order to do that, you need some background context and must know how to keep yourself safe, and when to call in an electrical professional.

Every electrical assessment boils down to safety, either the risk of fire from an overloaded electrical panel or electricity leaking into other parts of the building, causing shocks.

After assessing for safety risks, you need to collect information on whether the main service panel can handle the backflow from the new solar array. If the panel isn’t big enough or doesn’t have enough breakers, the homeowner will need to do an electrical upgrade before you can install solar.

What electrical information do I need to collect for a solar project?

Here’s what you ultimately need to collect for a Designer:

-

A picture of the whole wall where the main service panel is located (including the panel in the picture).

-

A context picture of the panel itself (zoomed in on the whole panel but nothing else).

-

Pictures of all stickers on or nearby the panel that provide more detail.

-

Close-up photos of the breakers and bus bar.

-

Close-up pictures of the wires (this requires removing the dead front).

This is the same for all homes. Where old electrical systems differ is the number of potential issues and additional safety measures you’ll need to take.

What electrical issues do I need to watch out for in older homes?

When assessing an old electrical system, you’re looking for three key issues:

1. Panel age and condition: Older panels–both main service and any subpanels–typically carry a higher risk of issues, especially if it’s not in great condition.

2. Wire size and insulation: Many older panels have smaller wires which can’t handle the backflow load from solar panels. Further, old insulation can break down over time, leaving electrical wires exposed that could shock you (or start an electrical fire).

3. Fuse boxes versus circuit breakers: Both fuses and breakers are meant to protect against electrical overload and prevent the risk of fire and damage. However, the presence of fuses could be an indicator that the system is older and may need to be inspected by someone familiar with electrical codes.

3 Steps to Staying Safe When Working with Old Electrical Systems

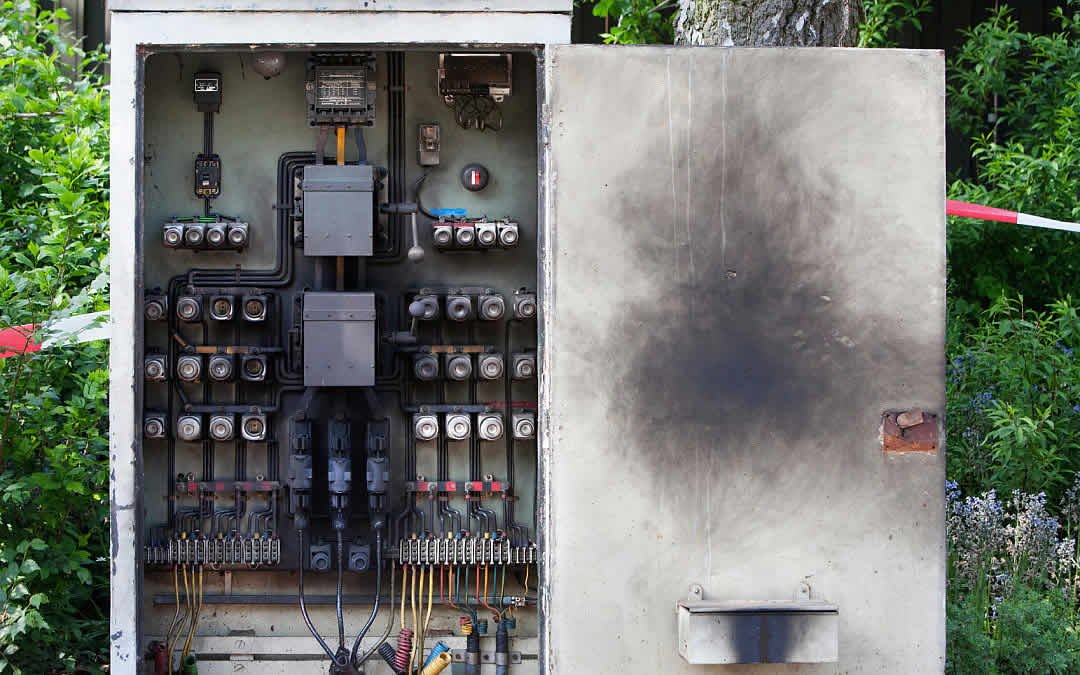

1. Analyze first: Look at the panel for any obvious marks like corrosion or burning. Then see if you can find the age of the panel (either from visual cues or information on the panel’s stickers).

2. Wear Personal Protective Equipment (PPE): This includes things like eye protection and wearing electric-insulated apparel (e.g. rubber boots, clothing, and gloves) to minimize the risk that you will be shocked or harmed.

3. Use insulated tools: Insulated screwdrivers are a particularly helpful tool; talk to your Contractor (or other members of your surveying team) to ensure you’ve got the right tools for electrical surveys.

Red Flags to Watch for with Old Electrical Systems

If you’re surveying an old electrical system, pay close attention for the following red flags. If any of these are present or you feel unsafe, document what you can by zooming in on your camera, but otherwise do not put yourself at risk. A properly trained electrical professional should be brought in.

Courtesy of John Moore Services

-

Noise: If the panel is buzzing or whirring, that’s a sign it could be malfunctioning.

-

Heat: Panels in working order are never hot to the touch–if it is, that could mean exposed or loose wiring.

-

Signs of damage: Scorching, burn marks, black marks on the screw fronts, and corrosion means that electricity has been hitting the panel (meaning exposed wires or a malfunctioning panel).

-

Pointed screws in the panel: The United States National Electric Code requires flat-end screws because a pointed screw can break through the wire insulation and deliver an electric shock.

-

Arcing: This is when a circuit has been opened or broken, but the electrical current jumps the gap between the two conductors (you’ve often seen this in old horror or thriller movies when someone flips a switch to turn a machine on). This always produces a bright flash–sometimes also a loud noise–and is a sign the panel is breaking down.

Your Job is to Collect the Right Data

Understanding the context of electrical surveys and knowing the right precautions makes it easier to do your real job–collecting information for Designers to ensure the project can move along safely.

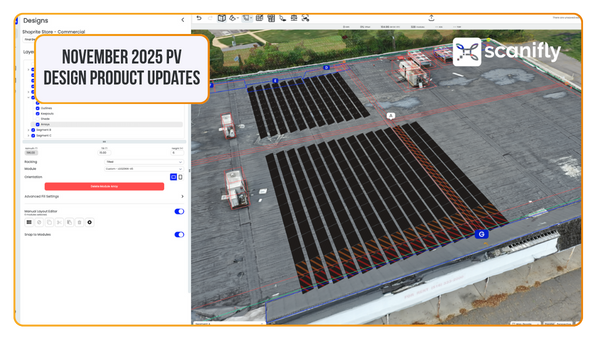

While an experienced surveyor might be able to spot red flags just from looking at a panel, it’s ok if you don’t fully understand everything yet. Just make sure you’re paying attention to obvious safety issues and then documenting everything possible. And if you’re using Scanifly Mobile, you can take and share pictures directly from the app to ensure Designers get what they need.

If you’re interested in learning more about electrical safety protocols, consider enrolling in OSHA-approved training with a qualified organization.