Customer Story

How Dynamic SLR Achieved a 100% Fit Rate with Scanifly

Company Overview

- Dynamic SLR was founded in 2017 and built a name for itself in the crowded Texas market by focusing on quality and accuracy.

- As the company grew, manual surveying methods took a significant amount of time—the leadership team needed a better solution.

- The team chose Scanifly and got amazing results: they saved hours per design and increased survey capacity while maintaining the accuracy and quality the company is known for.

“Other companies just give you the layout with 2D arrays. With Scanifly, you have more accuracy and flexibility. You can also generate precise production reports, which is a critical factor for us.”

The Challenge: Accuracy & Safety

Dynamic SLR was founded in 2017 with a goal of bringing incredible quality to the Texas solar market. Building a new business in a crowded space, the company stood out by prioritizing urban areas near Dallas-Fort Worth and Houston, building a name for themselves as caring local contractors.

Yet the company faced a challenge: using manual surveying methods, the team had to spend significant time climbing on roofs, manually measuring and drawing roof planes, and dealing with the “beast” of harnessing in for safety.

“Our surveys were primarily done manually,” said Jan Bautista, a Site Survey Coordinator at Dynamic.

We were using mechanical tools such as a measuring wheel on the roof. This led to issues.”

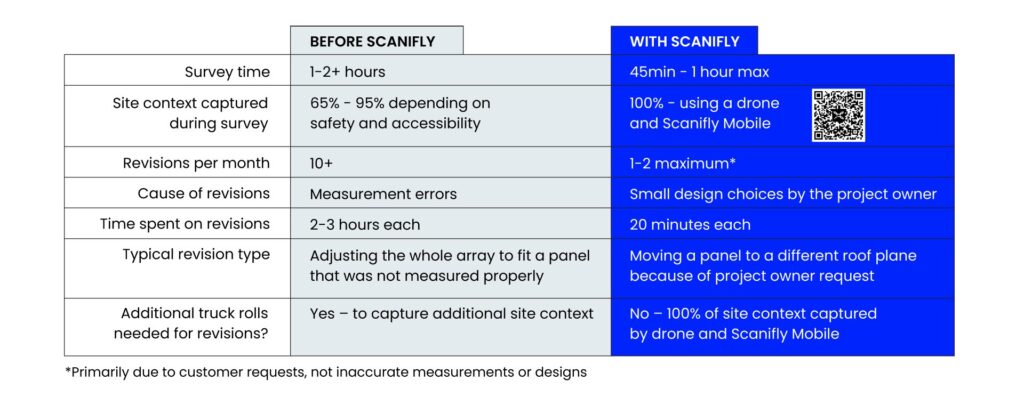

Not only did manual surveying take a lot of time, it was error prone. And when errors happened, the team had to revisit a site and spend even more time correcting the mistake. The team was spending 2-3+ hours per revision, which had both hard costs in terms of team time but also the soft cost of not delivering the type of customer experience they aim to provide.

To continue offering high-quality services while also scaling up the company, the Dynamic team began looking for a tech-enabled solution and ultimately chose Scanifly. Not only did this save the team hours per design, but it also resulted in a 100% fit rate for panels, meaning no revisions due to inaccurate measurements.

A 30-Property Trial with Scanifly

The Dynamic SLR team looked at several possible solutions and was excited by the opportunity to improve their survey and design workflows. However, they refused to compromise on quality for customers — even if the manual surveys took a lot of time, they knew it would ultimately be accurate.

Intrigued by Scanifly’s accuracy pledge, the Dynamic team decided to conduct a proof-of-value project with the platform. In total, the team flew 30 properties, both residential and commercial, and found multiple benefits:

1. Panel fit and 3D models: With manual measurements, sometimes panels didn’t fit on the roof due to a missed obstruction or misread data points. Further, the team could only show preliminary drawings to homeowners, which some didn’t think were sufficient enough to sign off on.

“[Using only remote designs] some homeowners will decide to cancel because they are unsure what it’s going to look like in the end,” said Jan.

With Scanifly, panels fit 100% of the time and homeowners can see the real-life design before signing the contract.

“Being able to show a photorealistic 3D model is really helpful here,” Jan added.

2. Flexibility: Pre-Scanifly, the team had to work with whatever data they could get. This meant skipping some roof planes if the area was dangerous or inaccessible, for example, which could lead to issues if project owners wanted panels moved to a different area for visual reasons. Further, production estimates were a manual process that took a lot of time.

With Scanifly, that’s no longer a problem; surveys capture all data and the team can easily create designs, move panels, and generate accurate production reports.

“Other companies will just give you the layout with 2D arrays,” said Jan. “With Scanifly, you have more accuracy and flexibility. You can also generate production reports, which was an important factor for us.”

3. Commercial enablement: Pre-Scanifly, the team was looking to break into commercial jobs but were concerned at the sheer size.

With Scanifly, the team was able to survey an 800 KW commercial project with ease.

“That commercial project got us thinking the old ways cannot be done and we need an innovative tool,” said Ahmad Awad, Lead Solar Engineer at Dynamic SLR. “With Scanifly, it took me 45 minutes to conduct the survey, and I could do it alone. But manually measuring would take two people 4-6 hours.”

Locking In For The Future

Working with Scanifly has helped Dynamic SLR become even more accurate and keep their team safer — all while saving time.

Looking ahead, the team is further streamlining operations but also looking toward bigger projects to scale up the company. In particular, growing more in the commercial solar space — a part of the industry the company couldn’t efficiently access before using Scanifly — while continuing to further the residential side and achieving their impressive 100% panel fit rate.

“That was a big thing, in terms of saving time on-site,” said Jan.