Case Study

Hammond Energy Eliminates Design Revisions & Cuts Survey Time by 84% with Scanifly

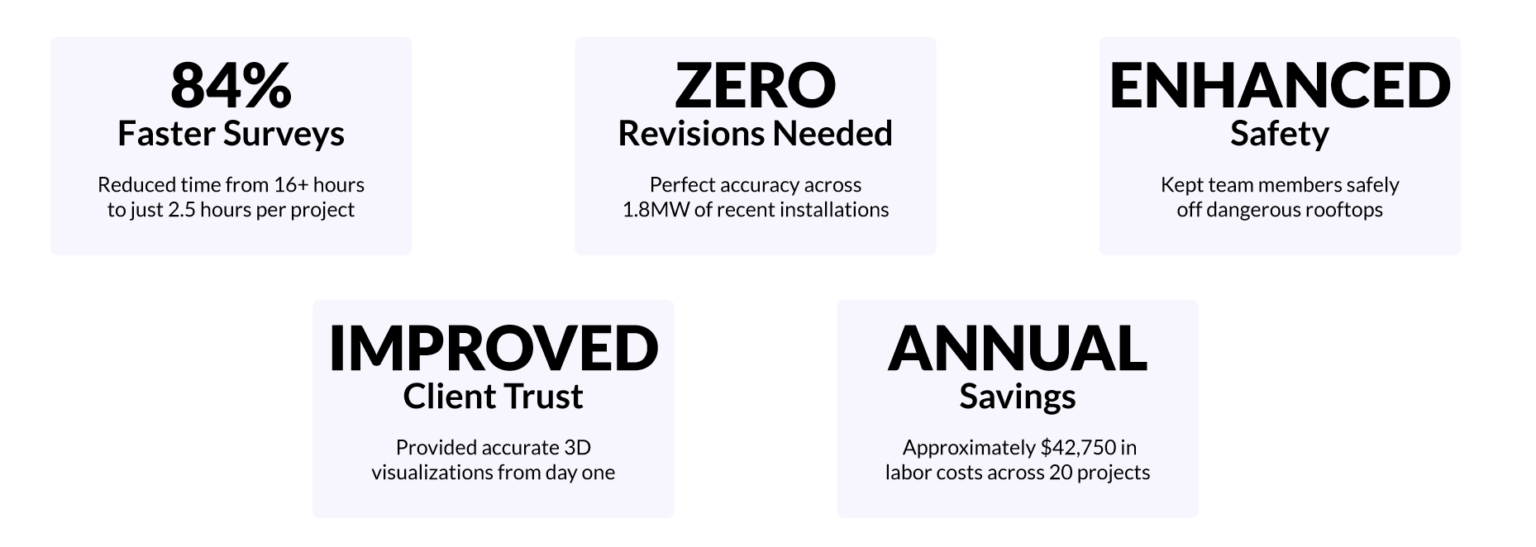

Results From Using Scanifly

Company Overview

Hammond Renewable Energy was founded after Ontario’s Feed-In Tariff (FIT) program ended, creating an opportunity for founder Sean Hammond to build a company that reflected his business values.

After working as a consultant and project manager on legacy FIT projects and providing O&M services, Sean developed a vision for Hammond Energy as a commercial solar design-build firm focused on quality and customer service.

“Our philosophy is pretty simple,” explains Sean. “Good communication with an emphasis on teaching and old-fashioned customer service. We repeatedly hear that other companies took weeks to call people back or didn’t do what they promised. We have a great team that can deliver quality and add value at all stages of a project.”

Hammond Energy has built its reputation by focusing on clients genuinely interested in cost reduction and environmental stewardship rather than pushing solar where it’s not wanted. This approach creates strong client relationships and drives steady growth through referrals.

The Challenge

Inaccurate Initial Designs & Dangerous Roof Measurements

Before adopting Scanifly, Hammond Energy faced significant challenges with their design process using traditional remote solar design tools:

- Limited mapping resources in Ontario, especially outside major urban centers

- Significant changes between initial designs and final layouts after site visits

- Difficulty visualizing solar installations for clients when using 2D images

- Safety concerns with manual roof measurements, especially on pitched steel roofs

- Weather complications affecting roof access for 10-12 months of the year

“In Ontario, we lacked robust mapping resources, and vendors didn’t offer LiDAR outside the major centers where 90% of our projects exist,” Sean explains. “We would complete a remote design to see if we could get a client interested enough to move ahead with a site visit and then have to measure the roof prior to finalizing a proposal or contract.”

The manual measurement process consumed significant time and put workers at risk:

“Two people on a roof for 2-8 hours, depending on complexity. Using a 100′ tape to try and measure >100′ roofs. Trying to figure out reference points for obstructions manually and plot them on the building properly. Seven months out of the year we could be dealing with frost or heavy dew, and 4-6 months we have a chance of snow on the roof. This was unsafe on pitched steel roofs and added difficulty and inaccuracy on flat roofs.”

These challenges prevented Hammond Energy from scaling the business efficiently while maintaining the high-quality standards they’re known for.

The Solution

Accurate Drone Surveys & Photorealistic 3D Models

Sean had already been using drones for some inspections and project progress photos when he discovered Scanifly. Excited about the potential, he ran it in parallel with his previous design software for 12 months.

“I realized that I hadn’t even opened Helioscope in over six months when I finally canceled our subscription,” Sean notes.

The drone-based approach immediately addressed Hammond Energy’s key challenges:

- Keeping teams safer by eliminating the need to access rooftops for measurements

- Capturing complete, accurate data of all roof surfaces and obstructions in a single flight

- Creating photorealistic 3D models that help clients better visualize their solar installations

- Providing precise measurements for both design and installation phases

- Integrating with other tools for a more streamlined workflow

Quantifiable Results: Time Savings & Perfect Accuracy

The impact of switching to Scanifly has been dramatic for Hammond Energy:

Dramatic Time Savings

For a recent 424kW system on a 13,600 sq ft rooftop:

Before Scanifly:

- 12-16 hours: Manual roof measurements

- 4+ hours: Round-trip travel time

- Multiple staff required on dangerous rooftops

- Total: 16-20+ labor hours

With Scanifly:

- 30 minutes: Drone flight

- 1.5 hours: Processing and design

- Zero roof access required

- Total: 2.5 hours (84% reduction)

This represents an 84% reduction in time spent on the survey and initial design phase.

Over the course of a year with 20 projects, Hammond Energy estimates savings of approximately $42,750 in labor costs.

Perfect Design Accuracy

“We have constructed our last 1.8MW without any revisions!” Sean proudly states.

The accuracy of Scanifly’s 3D models means that designs created in the platform match what’s physically possible during installation. This eliminates costly mid-project adjustments and ensures client expectations are properly set from the beginning.

Enhanced Client Relationships

Showing clients photorealistic 3D models of their buildings with solar arrays improves the sales process and strengthens client trust.

“I think it was difficult for clients to clearly visualize solar on their roof when they were looking at a 2D map image that was low quality,” Sean explains. With Scanifly’s photorealistic models, clients can see exactly what their installation will look like.

Project Showcase

Adventec Manufacturing

A recent project with Adventec Manufacturing highlights the benefits of Hammond Energy’s Scanifly-powered approach.

The project presented unique challenges: the roof supported a maximum system size that exceeded what they could simply connect to the existing switchgear. Armed with precise roof data from Scanifly, Hammond Energy developed an innovative solution.

“We were able to de-rate our inverters and install measurement and protection equipment to allow for a connection to the existing switchgear and protect the busbar to meet code requirements without any upgrades to the client’s existing service,” Sean explains.

The resulting installation matched almost exactly what the team modeled in Scanifly – a level of accuracy that’s become the standard for Hammond Energy projects.

An added benefit: “We also gave them great insight into their building consumption through 24-7 consumption monitoring,” providing ongoing value beyond the solar installation itself.

Adventec was impressed with both the process and outcome, noting that Hammond Energy “delivered on what they promised” – high praise in an industry where overpromising is common.

The Impact

Building Partnerships Through Trust & Technology

For Hammond Energy, using advanced technology like Scanifly is fundamentally about creating better partnerships with clients.

“We like to create partnerships. I know this term is over-used but we truly enjoy our client relationships and love when they get to a level of trust that allows them to relax during a very important investment for their business and let us take care of it,” Sean says.

By removing the uncertainty and inaccuracy that plagued previous design approaches, Hammond Energy can focus on what they do best: delivering high-quality commercial solar installations with exceptional customer service.

“The early stages of larger projects require a ton of work when done correctly,” Sean notes. “By taking the complexity out of the site survey and layout process, we can focus on the electrical infrastructure of the facility and design better solutions.”

Looking Ahead

Scaling with Quality

With the time and cost savings provided by Scanifly, Hammond Energy is positioned to grow while maintaining their commitment to quality and customer service.

“We see Scanifly as an investment in our business that pays dividends for our clients,” Sean says.

“We invest in solutions that directly benefit our clients and business while cutting costs in areas that don’t deliver value.”

This focus on process excellence and quality has become a key differentiator for Hammond Energy in the Ontario commercial solar market. By partnering with Scanifly, they’ve found a way to scale their operations without compromising on the values that have driven their success through word-of-mouth referrals.

As commercial solar continues to grow across Ontario, Hammond Energy stands ready to deliver systems that perfectly match client needs – designed with precision, installed with care, and built to last.