Customer Story

How Elemental Energy Replaced Manual Helioscope and SunEye Workflows with Automated, Revision-free Scanifly Designs

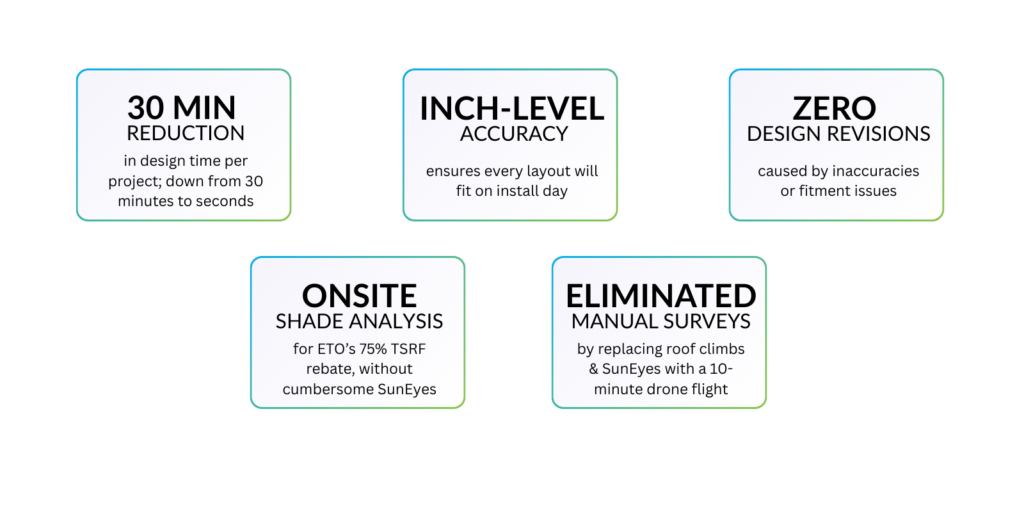

Results From Using Scanifly

Company Overview

Elemental Energy has built a reputation as one of Oregon’s most trusted residential solar installers. As a PV Design Manager with over 5 years at the company, Betzabel Osornio-Serna has experienced firsthand the challenges of keeping pace with both growth and quality demands.

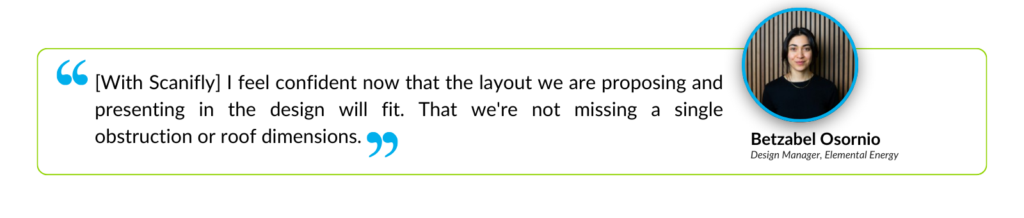

“The biggest problem was accuracy,” Betzabel explains. “[With Scanifly] I feel confident now that the layout we are proposing and presenting in the design is going to fit. That we’re not missing a single obstruction or roof dimensions.”

For Elemental Energy, serving residential customers across Oregon means handling everything from simple ranch homes to complex multi-plane roofs. Their commitment to accurate designs that fit on install day has been unwavering, but their old workflow made that commitment increasingly difficult to maintain as they scaled.

The Challenge: Solar Rebates Meet Obsolete Technology

For years, Elemental Energy relied on a labor-intensive, error-prone process. But these workflow challenges were compounded by Oregon’s unique rebate landscape, where on-site shading analysis determines project viability.

The ETO Rebate Dilemma

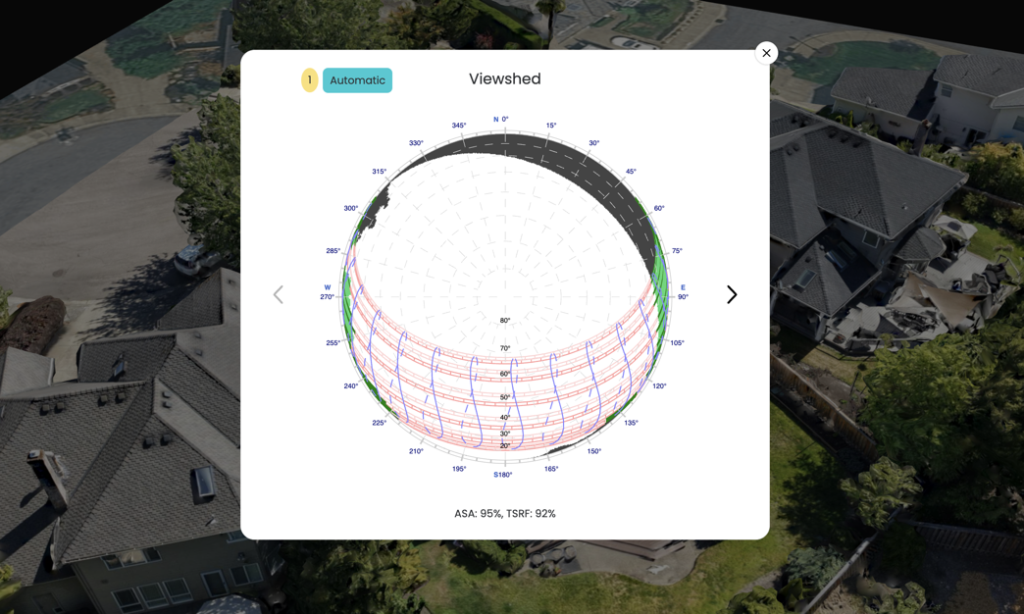

The Energy Trust of Oregon (ETO) provides significant rebates that can make or break residential solar economics. But accessing these rebates requires validated shading analysis that meets specific TSRF thresholds:

- Remote shade analysis tools (like Aurora): Require 80% or greater TSRF per array

- On-site shade analysis tools (like SunEye or Scanifly): Require only 75% or greater TSRF

That 5% difference determines whether certain projects, common in Oregon’s tree-lined neighborhoods, qualify for rebates or get canceled.

For years, Solmetric’s SunEye has provided the on-site analysis needed to hit that favorable 75% threshold. But by the time Betzabel was managing Elemental’s designs, the problems were mounting:

- Manufacturing discontinued; replacement parts impossible to find

- Site surveyors spent 60-90 minutes on roofs manually collecting roof measurements and shade data

- Safety concerns with climbing roofs in Oregon’s frequent rain

- A new SunEye costs more than a commercial drone

Some installers turned to remote tools like Aurora as a faster alternative, but the stricter 80% TSRF requirement meant many projects wouldn’t qualify. And ETO wasn’t always convinced by satellite-based outputs, leading to rejected rebate applications and customer cancellations.

Oregon installers were caught between obsolete technology and disqualification from rebates.

The Manual Workflow

Elemental’s daily operations involved a complex, manual process. Site surveyors would climb onto the roof and measure by hand, capture SunEye shade readings when weather permitted, photograph electrical panels and obstructions, and hand-sketch the layouts. Everything was uploaded to Google Drive and handed off to the design team.

Betzabel would then spend 10 to 30+ minutes piecing together the puzzle. Even with measurements and photos, some roof shapes were nearly impossible to draw accurately.

“There are some roof shapes that are so hard to draw in Helioscope. I was just hoping that what I was presenting would actually fit.”

Manual processes inevitably led to mistakes. Measurements were sometimes off. Practically every project was missing something.

The shade analysis workflow was equally cumbersome. The permitting team handled SunEye readings separately, consuming significant time and depending on aging equipment. For projects with marginal shading, accurate TSRF numbers determined whether Elemental could secure the rebates that made projects economically viable.

The Revision Cycle

The accuracy issues created a costly secondary problem that revealed a deeper systemic challenge.

With 5-6 projects landing on her desk daily, Betzabel faced a difficult choice: spend 30+ minutes perfecting each design with imperfect data, or keep the pipeline moving and address revisions as they came back.

“About half of the projects I would get, I would send them to the drafters without spending time on the layout in the first stage,” she explains. “Then it would come back, and the drafters would say, ‘Hey, there are obstructions here,’ or ‘The roof isn’t big enough.'”

This wasn’t a shortcut; it was the only viable workflow.

Spending the extra time scrutinizing hand sketches didn’t guarantee accuracy when the underlying measurements were incomplete or inaccurate. UNIRAC revisions cost $15 per project for layout changes, a known, manageable expense compared to the cost of bottlenecking the entire workflow.

When daily volume targets required moving 5-6 projects forward, and the site or satellite data is fundamentally unreliable, revisions became an unavoidable cost of doing business.

Beyond wasted time and costs, this approach affected job satisfaction. Complex roofs were a nightmare without reliable data, and Betzabel didn’t feel like we could confidently rely on the proposed layout for installation. But at the end of the day, she just didn’t have the tools to do it any differently.

The Solution: Scanifly's Onsite Shading & Automated Designs

Elemental had evaluated Scanifly a few years earlier, but without the automated roof outlines (Wireframes), it would have added more time to their design workflow.

When Elemental’s project managers anticipated a major surge in residential projects ahead of the ITC cliff at the end of the year, they reached out to Scanifly again. This time, the platform included Wireframes—inch-accurate 3D models with all roof planes and obstructions already traced and ready for panel placement.

But the timing was even more critical than they realized. Scanifly wasn’t just offering faster, more accurate designs—it was the only alternative to the SunEye that Energy Trust of Oregon certified for onsite shade analysis.

This meant Elemental could maintain access to the favorable 75% TSRF threshold while modernizing its entire site survey and design workflow. As SunEyes became harder to service, Scanifly offered a future-proof path forward.

The New Workflow

Before:

→ Site surveyor climbs roof for hand measurements and manual SunEye readings

→ Photos and hand sketches uploaded to Google Drive

→ Designer spends 30+ minutes creating designs in Helioscope

→ Permitting team processes SunEye data separately

→ Design sent to UNIRAC

→ Revisions on ~50% of projects ($15 each)

After:

→ Site surveyor conducts a 10-minute drone flight

→ Scanifly processes 3D model with Wireframes and onsite shade analysis

→ Designer places panels with just a few clicks

→ Reviews TSRF numbers for ETO rebates

→ Sends directly to UNIRAC via API integration

→ Revisions caused by fitment issues decreased by 100%

Integrated Shade Analysis

Previously, shade reports were handled separately using aging SunEye devices when weather allowed for safe roof access and equipment was functioning. Now Betzabel generates certified ETO shade reports herself in minutes using Scanifly’s proprietary shading analysis, with the same onsite accuracy standard and the same favorable 75% TSRF threshold as SunEyes.

“We noticed that when we get the TSRF from Scanifly, it’s lower, but we also know now that it’s more accurate,” Betzabel notes. The lower, more accurate numbers actually help homeowners qualify for better rebate tiers.

By maintaining onsite analysis certification through Scanifly, Elemental can still qualify marginal projects at the 75% threshold rather than the stricter 80% required for remote tools. For homeowners on the edge of economic viability, that 5% difference keeps projects moving forward instead of being canceled.

The Impact: Speed, Accuracy, and Confidence

Complex roofs that once took 30+ minutes now take just minutes to design. The Wireframe drone-based models eliminate the need to trace roof planes from scratch, and the photorealistic 3D environment makes it easy and intuitive to customize the array.

But the transformation goes beyond speed. It’s about certainty.

“I can feel confident that the layout we are proposing and presenting on the design is going to fit. That we’re not missing any obstructions or roof dimensions. That’s definitely the biggest benefit.”

While some revisions still occur at the customer’s or sales rep’s request, accuracy-related revisions are no longer a concern. Those are revisions by choice, not necessity—a critical distinction that makes for a much easier conversation with the homeowner and drafting team.

When Elemental faced an influx of 50+ residential projects in a short timeframe, Scanifly made the impossible possible:

“I keep saying I wouldn’t be able to do it without Scanifly because I got like 50 projects in a short period of time. It was one after the other, and designs had to be done quickly.”

Perhaps most importantly, the new workflow changed how Betzabel feels about her work. The nightmare of working with complicated roofs, knowing the design wouldn’t be accurate, is gone. Now she has the tools to overcome challenging projects with accuracy and efficiency.

As SunEye technology continues aging out of the industry, Elemental Energy has positioned itself ahead of the curve. They’re not scrambling to service obsolete equipment or losing projects to rebate disqualification.

Instead, they’re operating with modern tools that meet the same certification standards while delivering faster installs, safer operations, and comprehensive design data that manual measurements could never provide.

The Bottom Line: Onsite Data Shouldn't Slow You Down

For companies like Elemental Energy that refuse to compromise on quality, the right technology isn’t about cutting corners; it’s about having the tools to deliver on your promises.

“Scanifly replicates the house and its surroundings,” Betzabel explains. “You know that what you design is going to fit correctly on install day.”

After five years of working with incomplete information and hoping layouts would fit, Betzabel finally has the confidence that comes from accurate onsite data. And when the business demands surge, she has the speed to match.