Redesigns are a profit-eating nightmare in the solar world. Every time a contractor needs to change up the plan, a lot of downline things may be disrupted, such as supply ordering, installation planning, and even calling off the installation.

No one likes redesigns, yet in some way they are an accepted part of the solar process. However, it doesn’t need to be this way. By better understanding why redesigns happen in the first place, we can take preventative action to reduce or eliminate them altogether.

1. Satellite imagery isn’t good enough

Satellite imagery is commonly used in solar designs, but the vast majority of people (90%) say that satellite imagery is not completely reliable.

The good part about satellite imagery is that it’s quick, making it great for preliminary designs. But the bad part is that satellite imagery is often 2D or lower resolution, meaning it’s not accurate enough to inform comprehensive designs, which is where the issues with redesigns begin.

2. Sales pressure to max-fill a house

Salespeople are often partial- or fully-commission based, meaning they are incentivized to sell the biggest project possible in every instance. Unfortunately, there’s often a large difference between how many panels you can squeeze on a roof versus building a system that’s accurate to shading implications, roof pitches, and navigating roof obstructions.

When a salesperson max-fills a roof to impress potential customers, the designer is often stuck with the unpleasant task of making the designs smaller to actually fit with updated measurements. This adds a lot of pressure to designers since they are required to design for accuracy yet at the same time not jeopardize a sale.

3. Designers forced to prioritize speed over accuracy

Most design teams operate with some form of quota system, so designers have to hit a certain output per day or risk ramifications. The problem is low quality data inputs (from satellite imagery or manual drawings) or complex roofs lead to widely varying amounts of time per roof to get a “complete” design.

When a designer has to operate on a strict quota, they often end up prioritizing speed over accuracy. That means they may take shortcuts when designing complex roof systems because they don’t have the time to do it properly.

It’s worth noting that this dual issue – low quality inputs and shortcuts in design – are not the individual fault of surveyors and designers. They are doing the best they can with the manual tools they have. If surveyors were to use drones, for example, they’d get a much faster, higher quality output. It’s not about the person, it’s about the tools they are given and how that impacts the design process.

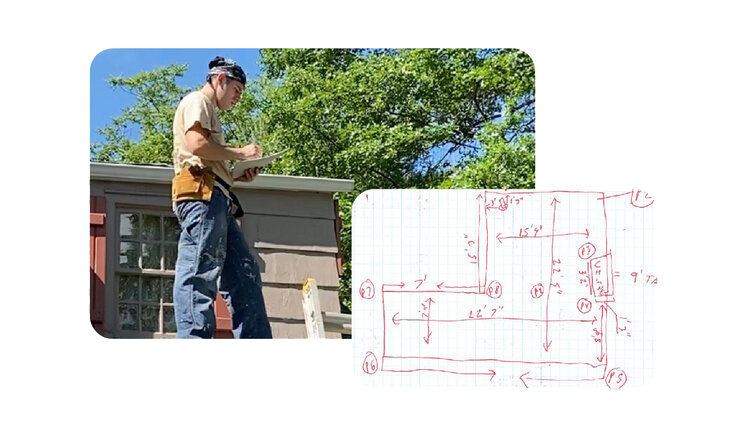

4. Onsite surveys are dangerous and difficult to capture measurements

Many site surveyors try to capture data without going on the roof due to safety concerns, roof complexity, or prioritizing speed in the surveying process. We don’t blame them for doing the best they can under pressure, but this makes it more difficult to capture accurate measurements (unless you’re using drones).

Even when surveyors do climb on the roof, they may not get comprehensive roof measurements because of steep pitches or angles that block them from accessing certain areas. In the end, this means designers don’t get the information they need.

5. Assumptions that the installer can “figure it out”

Most solar contractors assume the installer can figure it out as they go and clean up any errors in the design. While this is true in some cases, it doesn’t apply to every issue. Further, it’s unfair to installers and wastes time in the process.

The net result of this practice is more redesigns – or call-offs – if installers aren’t able to fix the problems themselves. Unfortunately, this also sows discord within the organization. Many installers don’t bring up issues unless they are so bad that someone needs to get blamed, which results in resentment between surveyors, designers, and installers, each of whom is doing the best they can with the information they have.

Better designs start with better data

Designers want to create amazing designs, but their intention needs to be supported by process and data. Redesigns are not an inherent part of the process – or at least they don’t need to be. They might still happen in emergency cases, but they shouldn’t happen with regularity. And the way to stop them isn’t to force designers to figure it out even more, but instead to solve underlying causes.