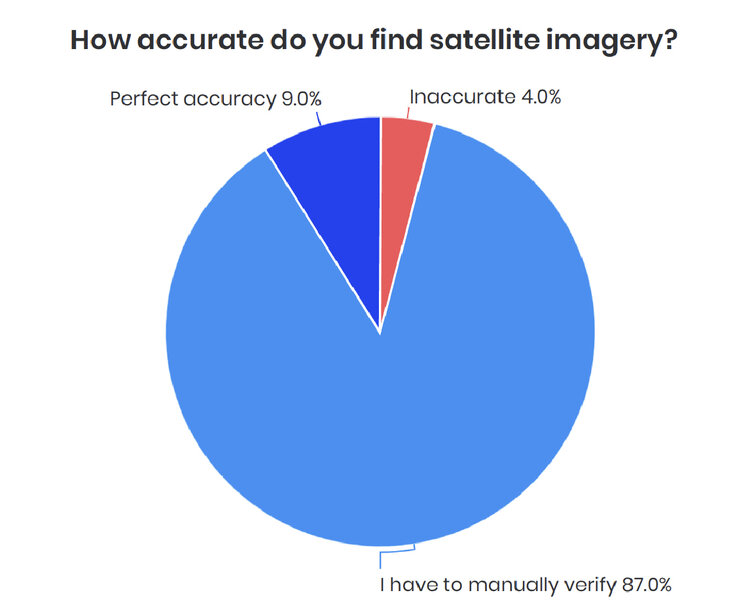

Demand for solar is rapidly increasing, but the industry faces significant challenges meeting that demand. First are project redesigns, which 44% of surveyors say happens to one tenth or more of their designs, according to the Scanifly Solar Surveyor Outlook. Another is over-reliance on satellite imagery, which 91% of surveyors say is not entirely accurate. These issues trickle down the project pipeline and can result in calling off a project on installation day, a costly and embarrassing mistake.

At Scanifly, we’ve helped contractors process tens of thousands of solar installations and avoid call-offs. Here are our top five tips for how any contractor can minimize or eliminate these issues.

1. Treat preliminary designs as only preliminary

Source: Scanifly Solar Surveyor Outlook

Many salespeople will use satellite imagery for preliminary designs. If you do this, that’s fine, but make sure you treat the preliminary design only as preliminary. Problems begin when contractors use a salesperson’s early design as the basis for the official design, since satellite imagery can easily be off by a foot or more.

To avoid a call-off, it’s important to acknowledge the truth: aerial imagery does not accurately reflect reality. Use satellite data for quick proposals, but confirm measurements using more accurate tools like drones.

2. Get onsite… even if only for 10 minutes with a drone

Getting actual onsite measurements is the first step to an accurate design that won’t lead to a call-off. In addition to roof measurements and shingle health, it’s important to assess the structural integrity of the property and electrical composition. But manual surveys with ladders and tape take anywhere from 30-90 minutes each. A drone is up to 5x faster and accurate to within a couple inches, meaning you can get an accurate survey done very quickly. Further, you can get a commercial drone license in a week, making it easy to implement this change.

For people who think satellite imagery is “accurate enough” to skip the onsite visit, consider this: even if 70-80% of satellite imagery is close to perfectly accurate, the remaining 20-30% could destroy your profits and lead to major reputational damage with call-offs and significant redesigns. It’s just not worth it.

3. Remove manual design work with AutoCAD

Done manually, solar designs can take hours or days, especially for complex projects with different roof lines or steep pitches that are hard to draw out by hand. Instead of needing hours of manual work, automatically create a DXF CAD export to streamline design. Not only will this be a far faster process (minutes, not hours), the designs will also be more accurate.

Drone-based work makes this automation even easier with near-perfect accuracy, adding another value proposition to doing an onsite drone inspection even if you only have 10 minutes.

4. Coordinate and communicate with homeowners

Coordinating with homeowners is easier said than done, but it’s critical to a smooth process. Here are three things you can do:

Installation booking: Offer a handful of days that a homeowner can pick for installation. Let them pick a day they can commit to, which reduces the possibility that you show up on installation day to an empty house.

Pre-installation communication: Send an email reminder about installation 15 days out, three days out, and the day prior to installation day. This gives you ample opportunity to tell the homeowner what you need from them on installation day and give them the opportunity to reach out if an emergency arises and they need to reschedule.

Use Technology: There are several products being developed that enhance customer success in the solar industry. Bodhi has created a mobile app that uses automation tools to streamline that process and centralize all customer data in one place.

5. Conduct pre-installation prep meetings

In many cases, the first time installers see the full property is on installation day. They spend precious hours walking the property and climbing on the roof to get a sense of the space, taking up time that should be spent on installing panels. For a big project, this can lead to a call-off.

To avoid this time-waster, do two things:

1. Come with extra equipment: A large reason behind call-offs is realizing something onsite that no one knew about before. If you have extra equipment, including solar modules, rails and other components, you reduce this risk.

2. Have installers look at a 3D model of the full site in advance: Scanifly has share-links that make it easy to send full 3D models to everyone on the installation team, which helps them get a better sense of the space before they arrive on installation day.

Don’t let a call-off ruin your reputation and bottom line

Call-offs are one of the most embarrassing client-facing blunders that can occur on a project. Regardless of who is at fault, it reflects poorly on you as the solar contractor. By using technology, spending a few minutes on site, and increasing communication, call-offs can almost entirely be eliminated, freeing up much-needed capacity to tackle the massive demand solar energy is seeing across the country.