Increasing interest rates and rising energy costs have pushed more homeowners to consider leasing over financing or paying cash for their arrays.

Financed deals don’t require accurate system designs. The financing company is actually underwriting the credit of the customer, and not of the array. Accuracy is more important for the customer, who is significantly affected by overall net savings and economics.

Conversely, lease providers (also called Third Party Owners or TPOs) require optimal accuracy because they own the systems and rely on them for their economic model. TPOs underwrite the project itself, specifically its production.

Currently, many Contractors leverage outdated, pixelated, or 2D remote imagery and manual design processes to estimate production. While commonplace, this approach is a subjective form of modeling a PV system. This leads to change orders and financing rejections, which can delay deals, reduce sales commissions, and force Contractors into carrying the cost of the project for longer than anticipated. Furthermore, homeowners are left feeling bait-and-switched.

This friction can be solved with a better process.

What an ideal process needs to achieve

An ideal process has to address the needs of all parties involved.

For Contractors

Contractors want to minimize cost outlays until contracts have been signed (and any legally mandated cooling-off periods are over).

Further, they want to shorten the overall cost outlay period, minimizing the time between their procurement costs and when they get paid by TPOs.

For TPOs

TPOs want their economic model to work, which relies on the initially agreed-upon array and production forecast being installed with few, if any changes. Beyond that, they want a quick SLA process with objective data that makes it easy to review, make specific requests to fill any potential gaps, and close the job without re-reviews and re-rejections.

For Homeowners

Simply put, homeowners want the same (or close to) system size and offset they were told they’d get in the initial sales proposal. They want to maximize their production as best as possible and economically sensible.

For All Parties

All parties want limited friction in the relationship and higher confidence from the start that the initially agreed-upon plan is what will get installed.

The ideal process in three milestones

The ideal process follows the traditional three-milestone path; the shift is to achieve perfect accuracy before the project is completed while minimizing the cost to Contractors.

For Milestone 1: Initial agreement

In an ideal process, Milestone 1 planning has two crucial needs—set up the initial agreement and deliver the highest-possible confidence that there won’t be significant revisions before Milestone 2.

Here’s what Contractors should prepare for Milestone 1 submissions:

1. Have a Sales Rep conduct a conservative preliminary design

Design a PV system using the best remote data you have, including leveraging various satellite imagery providers, Nearmap’s airplane data, LiDAR and Google3D. Be conservative in your assessment, potentially using larger setbacks or placing taller trees in the scene to avoid over promising on production. It’s important to communicate to the customer that a preliminary design is, well, just that – preliminary. It is an best guess estimate, and may have a “true-ing up” post signature.

For ambitious sales reps, we recommend flying a drone and collecting photos pre-signature, which pulls forward any accuracy or change order concerns. It can also help improve close rates by 20% or more. Despite some initial training, a sales rep can make the time back immediately in terms of capacity boost and efficiency.

2. Have the Sales Rep collect site information, if they can

Internal surveying doesn’t require too much technical knowledge up front—it’s about documenting all relevant information for Designers about the roof structure and the home’s electrical information. If a customer is leaning in, having a sales rep capture whatever info possible will be helpful. This step will help spot any issues that could cause major revisions or kill the deal entirely.

Reps are usually already onsite for the sales conversation; collecting all the data available at this stage makes the entire process easier.

If the Rep cannot collect the data, then it will be done by a Surveyor and submitted in Milestone 2 (see below).

3. Conduct a brief utility bill review

This task helps avoid delays by confirming the estimated production is in line with the homeowner’s electrical needs and any rate caps that apply in your area.

4. Title verification

Confirming a clear title helps form the basis of a lease contract, which is typically run by the TPO fund. The Sales rep may check for complications with the property’s title, such as whether the home is under an LLC or trust.

For Milestone 2: Notice to Proceed (NTP)

Milestone 2 will be an easy review step if you collect onsite documentation for Milestone 1. This can lead to TPOs quickly paying out 80-90% of the array’s value. Most contractors, however, do a site survey post-signing, and follow the below steps.

1. Site survey checklist & drone images

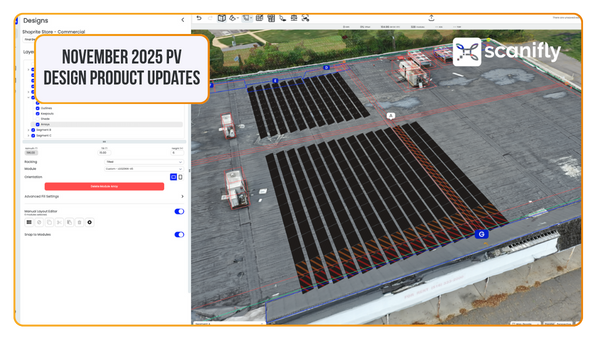

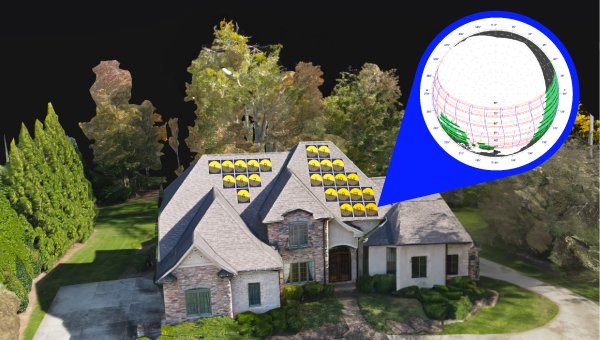

Use a mobile app with checklists (see Scanifly Mobile) to digitize all electrical, structural and property data. Fly a drone to capture all of the surrounding roof, facade, and tree information and generate a photorealistic model of a property, with measurements and tree heights automatically included.

This centralizes all data in one place and eliminates any guesswork on bad tape measuring or guessed tree sizes.

2. Conduct a true-up, including an onsite shade report:

Generate an onsite design and shade analysis using the photorealistic model produced from the drone data, and referencing the preliminary design submitted at Milestone 1. This process ensures perfect fitment and no revisions on install day while reducing up to 90% of survey and design process time. It also removes all of the subjective manual data collection and design habits that lead to high TPO rejection rates, which are especially agonizing at Milestone 2 where the majority of funds are typically paid.

3. Finalize CAD drawings and plan sets

Create and submit stamped plan sets accepted by local jurisdictions and permitting boards.

4. Contract and permitting document review

This is only necessary if there are change orders, which typically occur when production is outside of a contracted tolerance — if not, the contract from Milestone 1 will remain unchanged.

5. Install checklist

Some TPO funds want to review an Install checklist, which confirms the as-built matches the plans, and that the system was built as intended.

For Milestone 3: Commissioning

Milestone 3 is completed when the array is commissioned. This is also when the rest of the funds are paid to the Contractor—typically between 10-20%.

The ideal process at this step is a simple administrative review, finalizing a few things:

- Verifying the utility letter confirming permission to operate

- A final review of the inverters and electrical panel

- Ensuring the asset manager is set up to view system production

- Final check to verify the array is working properly

Fix friction with process

While incentives have put TPOs and Contractors at odds on some things, the end result is the same: both want a working solar array installed. Contractors want this done at the lowest cost, while TPOs want an efficient process where the initially promised array is what ultimately gets built and commissioned.

This friction seemingly had no resolution—subjective data collection and manual design work were an accepted part of the process, and everyone was stuck with the consequences. However, new technology makes it possible for all parties, while delivering the right balance of accuracy, time savings, and cost controls for everyone.