Lease financing providers (called Third Party Owners or TPOs) require a variety of data to issue milestone payments.

While initial estimates are often enough to get a project started, any errors or omissions need to be trued up; if they aren’t, TPOs may reject a submission and kick more work back to the Contractor.

Rejections are most common in situations where Contractors over-rely on remote imagery-based analysis for shading and where site data might be missing or incomplete—here are the top four reasons for TPO rejections and how to avoid them.

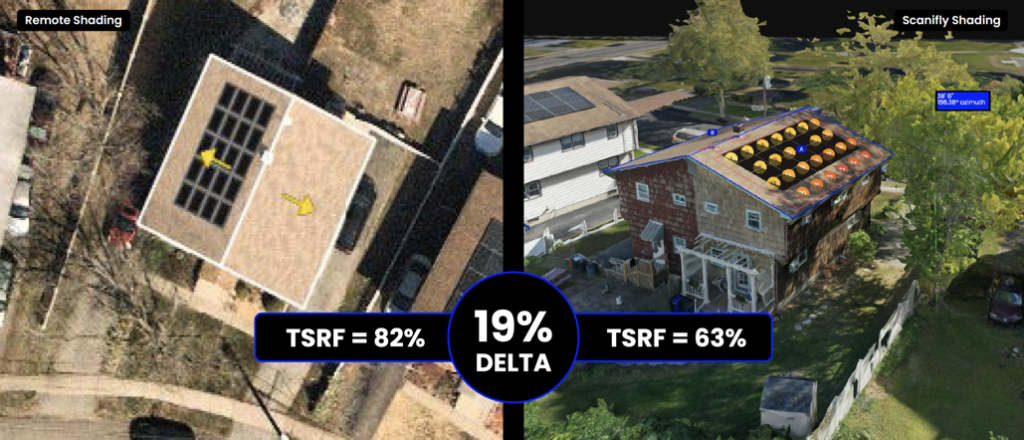

1. Incorrect or missing shade analysis

Shading analysis issues are the most common reason for rejections — 40% of rejections are tied to shading. This occurs because TPOs are mindful of maintaining production and offset, so forecasting the actual system performance as closely as possible is essential for project economics.

Shade-related rejections often occur from incorrectly modeling parts of a scene:

- Incorrect tree heights and tree removal

- Ignoring vegetation and growth rates, particularly for dormant deciduous trees

- Outdated LiDAR showing smaller or different vegetation

- Incorrect tilt

- Ignoring dormers, gables, and other roof structure obstructions

- Ignoring nearby buildings and topography

For a historical context on the arc of shade tools, the residential solar industry in the early 2000s leveraged physical shading devices, like the Solmetric SunEye, that were accurate if operated properly but were cumbersome to use. As a result, Surveyors sought alternatives; improvements in satellite imagery made it possible to use remote data.

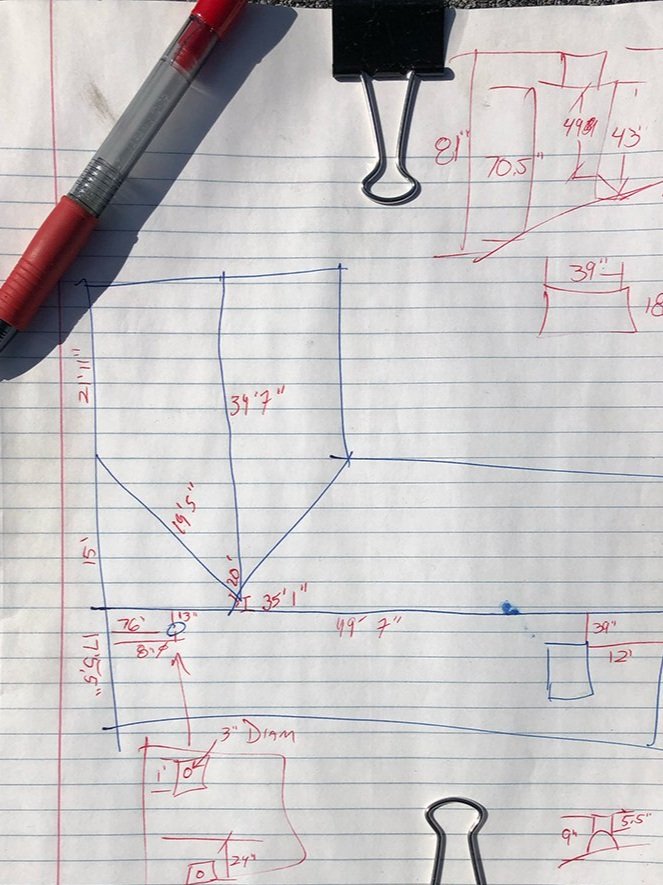

Over time, it has become clear that remote data are not as accurate due to image graininess and outdatedness: roughly one-third of satellite imagery-based shading studies are off by >10% from the reality of the site. Further, nearly all (92%) of surveyors say they have to manually verify satellite images. Because remote design tools are mostly 2D, PV system Designers need to scale the house, obstructions, and surrounding environment manually. This is a fairly subjective process using best guesses for the size of property details and is the biggest contributor to shading TPO rejections.

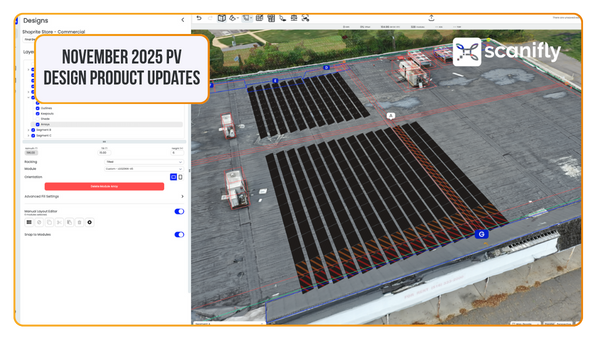

In the 2020s, further improvements were developed: Scanifly’s drone and photogrammetry-based tool quickly became the “new SunEye.” Its shade tools are approved by all major state regulators and finance companies.

Shading can now be comprehensive and fully accurate using real-time drone data.

2. Inaccurate production estimates

Even with good shading analysis, production estimates can be inaccurate if roof measurements are incorrect. For instance, if you don’t properly measure tight spaces or roof obstructions, you could end up with a different size array than initially promised.

From a TPO perspective, the issue is fitment and correct module placement in between the initial agreement (Milestone 1 of 3) and array installation (Milestone 2 of 3). If Contractors get approved on the initial plan but install something different (ie change order), the entire contract could be changed after installation or commissioning (Milestone 3)

Drone and photogrammetry-based models, on the other hand, produce 100% fitment—just ask Contractors like Dynamic SLR and Namaste Solar, who no longer have layout accuracy revisions.

3. Missing details on hardware or other

internal data

Without a proper internal survey, especially a comprehensive structural and electrical analysis, a lot

of details can be missed.

Pre-install issues tend to be process or information-related, such as:

- Not spotting necessary electrical or roofing upgrades until after signing the contract—and possibly not until install day

- Simply forgetting to capture data or not being educated enough to do so

- The name on title not matching the name on the contract

- Other HOA specifics

Issues spotted early in the process can be fixed, though this may result in expensive change orders, additional truck rolls, and deal delays that will likely impact overall contract value and Rep commission.

Post-installation problems are typically more hardware-related:

- Electrical box is not large enough for the array

- Code violations

- Workmanship issues

- Wire management for utility connection

If issues are spotted after installation, the lease provider may hold out on Milestone 2 or 3 payments until the issue has been addressed. This means Contractors have to both carry the cost of the project and the cost of any fixes.

The better path is to avoid a situation where you miss details. This is where documentation tools like Scanifly Mobile are incredibly valuable—not only does it include best-practice checklists (so you don’t forget to collect anything), it centralizes all data so nothing is lost in translation between Surveyors and Designers.

4. Inconsistent or incomplete site data

If you’re collecting data manually, chances are you may occasionally or generally take shortcuts and use overly conservative estimates to compensate for potential errors—in all cases, you’re only getting “accurate enough” data.

Even with the right tools, you still need comprehensive checklists to ensure you collect all the data.

Think about this like safety checks on airplanes, for instance. Even the most experienced pilot will go through a safety checklist before every flight—it’s not about insulting that pilot’s intelligence, but guaranteeing they confirm every small detail.

The same applies in solar: no matter your experience, a checklist ensures you get everything you need without having to wonder if you’ve forgotten something.

A solution for TPO rejections

Financing delays and rejections are not entirely the Contractor’s fault; sometimes, subjectivity creeps in on the TPO side in the form of multiple reviewers, each with their own perspectives. However, the core issue remains the same: submitting subjective data opens up room for subjective analysis.

The solution rests with Contractors: deliver objective, on-site, real-time data during the initial agreement (Milestone 1) phase, and there won’t be an issue with delays or rejections later on. Or, provide onsite data in Milestone 2, and be prepared for and communicate a design True Up, which is hopefully just a marginal one.

In the past, this might have been a huge ask with cost implications attached. New technology is not only affordable to invest in, but the cost of a drone program can actually save Contractors money in terms of insurance premiums and other operational costs.

In the end, this tech-forward evolution will not only make a Contractor’s life easier but also help speed up the PTO process and ensure the customer gets the array they were promised.